Noticias PPS

Martes 19 Abril 2022

PSS presente en en la AOG2022

Estuvimos presentes en la Argentina Oil & Gas 2022 donde tuvimos la oportunidad de compartir nuestra visión de la industria y los avances de nuestra empresa

Lunes 04 Abril 2022

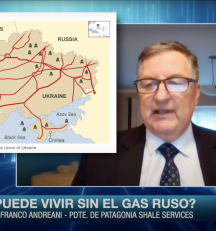

PSS en los Medios - Análisis: "¿Se puede vivir sin el gas ruso?"

Gian Franco Andreani, vicepresidente de Patagonia Shale Services, fue invitado a compartir su visión global sobre la situación de la gas y la energía frente al conflicto Rusia-Ucrania, en el programa ENERGÍA LATAM.

Lunes 14 Marzo 2022

PSS presente en África Oriental

PSS participará en el mayor oleoducto con revestimientos térmicos del mundo

Lunes 03 Mayo 2021

Innovación en la unión de tuberías mediante interferencia mecánica

La revista “Prensa Energetica” publicó un artículo en dónde se describen las ventajas tecnológicas del sistema PATSSLOK® desarrollado por PSS.

Lunes 16 Diciembre 2019

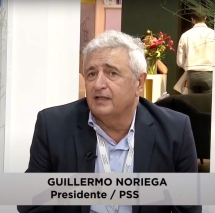

PSS en los Medios: Entrevista para la revista Petroquímica

La reconocida revista latinoamericana del rubro energético entrevistó a Guillermo Noriega, presidente de PSS.

Martes 19 Noviembre 2019

PSS certificó nuevas unidades de negocio

Durante el mes de noviembre se realizaron las auditorias correspondientes a la certificación de dos nuevas unidades de negocio de PSS.

Martes 24 Septiembre 2019

PSS en la AOG 2019

PSS estuvo presente en la XII Argentina Oil & Gas Expo 2019 presentando su novedoso sistema PATSSLOK®

Miércoles 11 Septiembre 2019

PSS Presentó un arenoducto como solución logística para Vaca Muerta

Patagonia Shale Services una de las nuevas empresas que nacieron a partir de la explotación de Vaca Muerta, ha desarrollado un novedoso proyecto para solucionar el problema de la excesiva cantidad de camiones necesarios para transportar la arena de fractura a Añelo.

Viernes 03 Mayo 2019

Patente INNERBOND® en EE.UU.

PSS recibió la certificación oficial por la oficina de Patentes de EE.UU.

Viernes 13 Abril 2018

PSS registra patente en EE.UU.

La empresa argentina registró su linea de productos INNERBOND®, una familia de revestimientos internos que otorgan alta resistencia mecánica a tuberías de acero.